成功的案例分享

Optics shapes your vision,

一些成功项目的共享

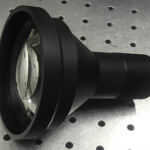

Bio Spectrometer is for a handheld portable device using a disposable tip for photometric analysis offering independence from a laboratory environment. It is the first personal photometer of its kind, and delivers similar wavelength capabilities of existing photometers in a palm-size.

The application of the biospectrometer is :

- Protein concentration

- DNA and RNA concentration

- Turbidity Measurements

In this project, the role of our company was Optical design, optical components fabrication coordination and technical support.

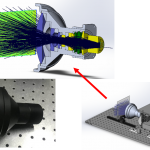

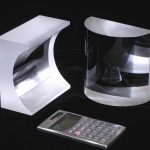

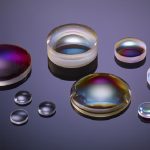

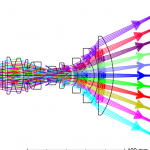

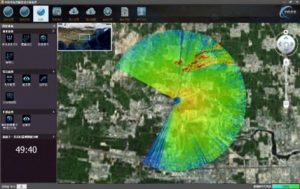

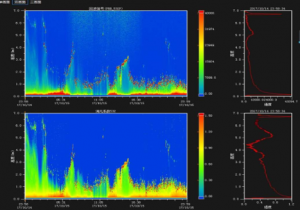

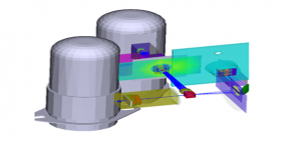

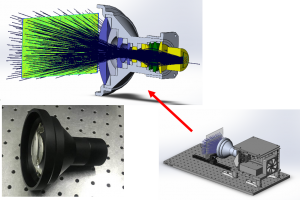

Recent developments in autonomous vehicle instrumentation has led to advancements in laser based LiDAR sensors. For these type of systems, sensor performance is dependent on fast response time and good contrast (SNR) at long distances. Careful design for the optical transmitter assembly is paramount to achieving good device performance, and has become a primary differentiator between emerging LiDAR technologies. These systems rely heavily on both the source emitter quality as well as the conditioning and delivery of collimated beams using passive optical components.

Most available sources, from semiconductor to fiber lasers, have the necessary spectral characteristics, but lack the required beam quality for long distance propagation and detection. In order to overcome these limitations,Shapeoptics leverages decades of experience in precision molded aspheres and fiber delivery systems to achieve quality collimation and astigmatic beam correction.

The role of our company in this product development was :

- Design the optical system,

- Produce the prototype,

- Test the optical system performance,

- Conduct the optical characteristics measurement,

- Manage other suppliers and support customer production.

.

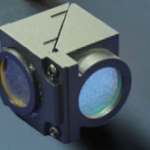

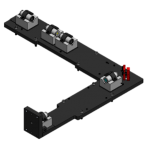

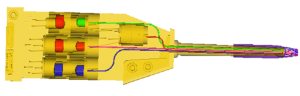

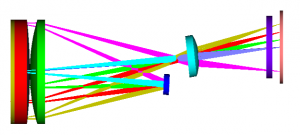

Laser marking and inspection optical engine is for a smart and compact imaging and marking system. It is used with a laser scanning system in material processing where precise positioning is required. The state-of-the-art technology is based on the simultaneous co-axial operations of digital image and laser scanning. The precise laser firing position is automatically adjusted with the help of the inspection system.

The system is ideal for various applications, such as ablation, cutting, scribing, marking, engraving, etc.

In this project, the role of our company was to design the optical system, which includes the f-theta scanning lens, and vision inspection system using CCD detector, as well as the optical prototype components fabrication, prototype assembly, testing and optical characteristic measurement.

Tele-centric Lenses are ideal for use in a variety of applications, including metrology, gauging, CCD based measurement, or microlithography due to the beauty of the centroid of chief ray in each field is parallel to the object or image.

In this system, a tele-centric lens was deigned in the scanner system in order to eliminate parallax error, at any distance from the lens, a tele-centric Lens will always have the same field of view. Moreover, the tele-centric lens comprises part of the inspection vision system, which eliminate the concern about measurement errors that would otherwise occur due to factors such as a vibrating conveyor or inexact part locations in the cutting and drilling process.

In this project, the role of our company was Optical design, optical components fabrication coordination and technical support.

The 3D profilometry inspection system is for 3D object profile measurement , which integrated with DMD chip through phase-shifting techniques. And phase-shifting profilometry technique is based on the projection of digital interference patterns and computation of the absolute phase map. It offers a fast, robust, and full field measurement for field sizes from approximately 1mm^2 to several cm^2.

This Non-scanning, non-contact technologies are able to measure the surface topography within a single camera acquisition, XYZ scanning is no longer needed. As a consequence, dynamic changes of topography are measured in real-time, hence it could be used for many application fields which require 3D data.

In this project, the role of our company was optical system design, including projection system and illumination system, optical components selection and fabrication, algorithm testing and optical system characteristic measurement.

The engine is for anti-counterfeiting, security and brand protection solutions nonClonableID™. The solution enables products to be authenticated as they move through the supply chain to the end consumer

nonClonableID™ employs unique materials-based fingerprints that are prohibitively difficult to copy. These tamper-evident fingerprints are irreproducible and cannot be duplicated. As those unique fingerprints are generated out of randomly distributed micro and nano particles, and then a proprietary scanning device scans the fingerprint and instantly communicates the encrypted information with a secure server through mobility platforms such as GPRS, 3G or Broadband.

The touch optical engine in this device is to read those “fingerprints” materials.

The role of our company in this product development was :

- Design the optical system,

- Produce the prototype,

- Test the optical system performance,

- Conduct the optical characteristics measurement,

- Manage other suppliers and support customer production.

A urine analyser is a device used in the clinical setting to perform automatic urine testing. The units can detect and quantify a number of analytes including bilirubin, protein, glucose and red blood cells.

The device normally is comprised of a illumination system and detection system ( microscope objective). The original illumination system was using a fiber bundle to transfer a white LED to sample plane, which induces non-uniformed illumination and cell shadow, and low power efficiency.

The new design was using a pair of standard stock lens, which is cheaper and Compatible with 10x -50x micro-objective, Anti-vibration & temperature change with high power white LED.

The role of our company in this product development is :

- Design the optical system,

- Produce the prototype,

- Test the optical system performance,

- Conduct the optical characteristics measurement,

- Manage other suppliers to support customer production.

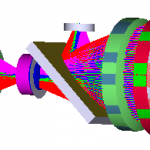

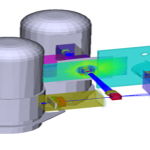

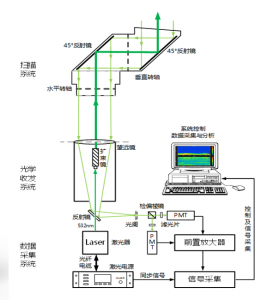

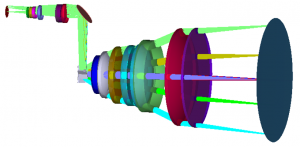

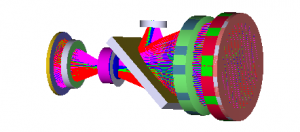

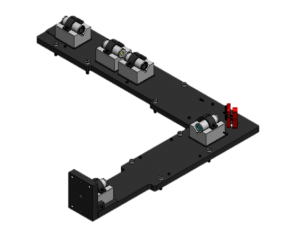

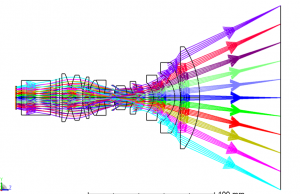

Flo w cytometry is a widely used method for analyzing the expression of cell surface and intracellular molecules, characterizing and defining different cell types in a heterogeneous cell population, assessing the purity of isolated subpopulations and analyzing cell size and volume. It allows simultaneous multi-parameter analysis of single cells.

w cytometry is a widely used method for analyzing the expression of cell surface and intracellular molecules, characterizing and defining different cell types in a heterogeneous cell population, assessing the purity of isolated subpopulations and analyzing cell size and volume. It allows simultaneous multi-parameter analysis of single cells.

Forward and side scattered light and fluorescence from stained cells are split into defined wavelengths and channeled by a set of filters and mirrors within the flow cytometer. The fluorescent light is filtered so that each sensor will detect fluorescence only at a specified wavelength.

The role of our company in this product development was, work with customer engineers to design the optical-mechanical system (laser beam shaper, polarization, light scattering, illumination, and imaging module ) for 5 partition blood cytometer, select the key optical components, produce the prototype, validate the prototype performance.

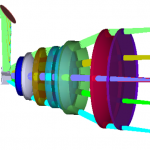

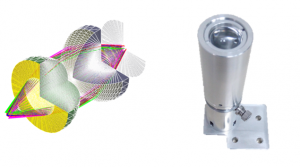

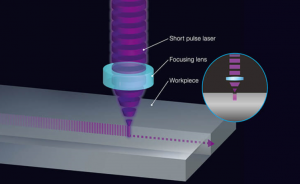

Stealth dicing is a zero-waste, dry process which does not require any cleaning in the MEMS wafer applications. SD in our design is a two-stage process. Firstly, the laser beam was transformed and then is focused into multiple focal points in the inside of the work piece creating a so-called modified layer/SD layer. Secondly, in order to separate the dies, external force is applied to separate the dies along the modified layer.

The role of our company in this research project was :

- Design the optical system ( optical beam shaper)

- Design the alignment and calibration tools

- Produce the prototype,

- Test the optical system performance,

- Conduct the optical characteristics measurement

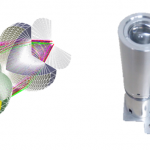

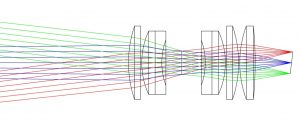

3-D Printing is the additive manufacturing process of building a three-dimensional object by laying down successive layers of material. For each cross-sectional slice of the object, the TI DLP® DMD (Digital Micromirror Device) projects patterned light that selectively exposes and hardens the resin.

Because an entire layer is exposed with a single pattern, fast build speeds are achieved. Projection optics can be used to control the resolution on the image plane and adjust the layer thickness, leading to smooth and accurate finished parts

In this project, the role of our company was:

- Align with customer and define the projection lens specs.

- Design the optical system (Projection lens)

- Produce the prototype for evaluation

A telescopic sight, commonly called a scope, is an optical sighting device that is based on a refracting telescope. It is equipped with some form of graphic image pattern (a reticle) mounted in an optically appropriate position in its optical system to give an accurate aiming point. Telescopic sights are used with all types of systems that require accurate aiming but are most commonly found on firearms, particularly rifles.

The role of our company in this product development was:

- Design the optical system,

- Produce the prototype,

- Test the optical system performance,

- Conduct the optical characteristics measurement,

- Manage other suppliers and support the customer production.

A night-vision device (NVD), also known as night optical/observation device (NOD) and night-vision goggles (NVG), is an optoelectronic device that allows images to be produced in levels of light approaching total darkness. The image may be a conversion to visible light of both visible light and near-infrared, while by convention detection of thermal infrared is denoted thermal imaging. The image produced is typically monochrome, e.g. shades of green. NVDs are most often used by the military and law enforcement agencies, but are available to civilian users. The term usually refers to a complete unit, including an image intensifier tube, a protective and generally water-resistant housing, and some type of mounting system. Many NVDs also include optical components such as a sacrificial lens, or telescopic lenses or mirrors.

The role of our company in this product development is :

- Design the optical system,

- Produce the prototype,

- Test the optical system performance,

- Conduct the optical characteristics measurement,

- Manage other suppliers and support customer production.

认识我们的一些客户

他们相信我们