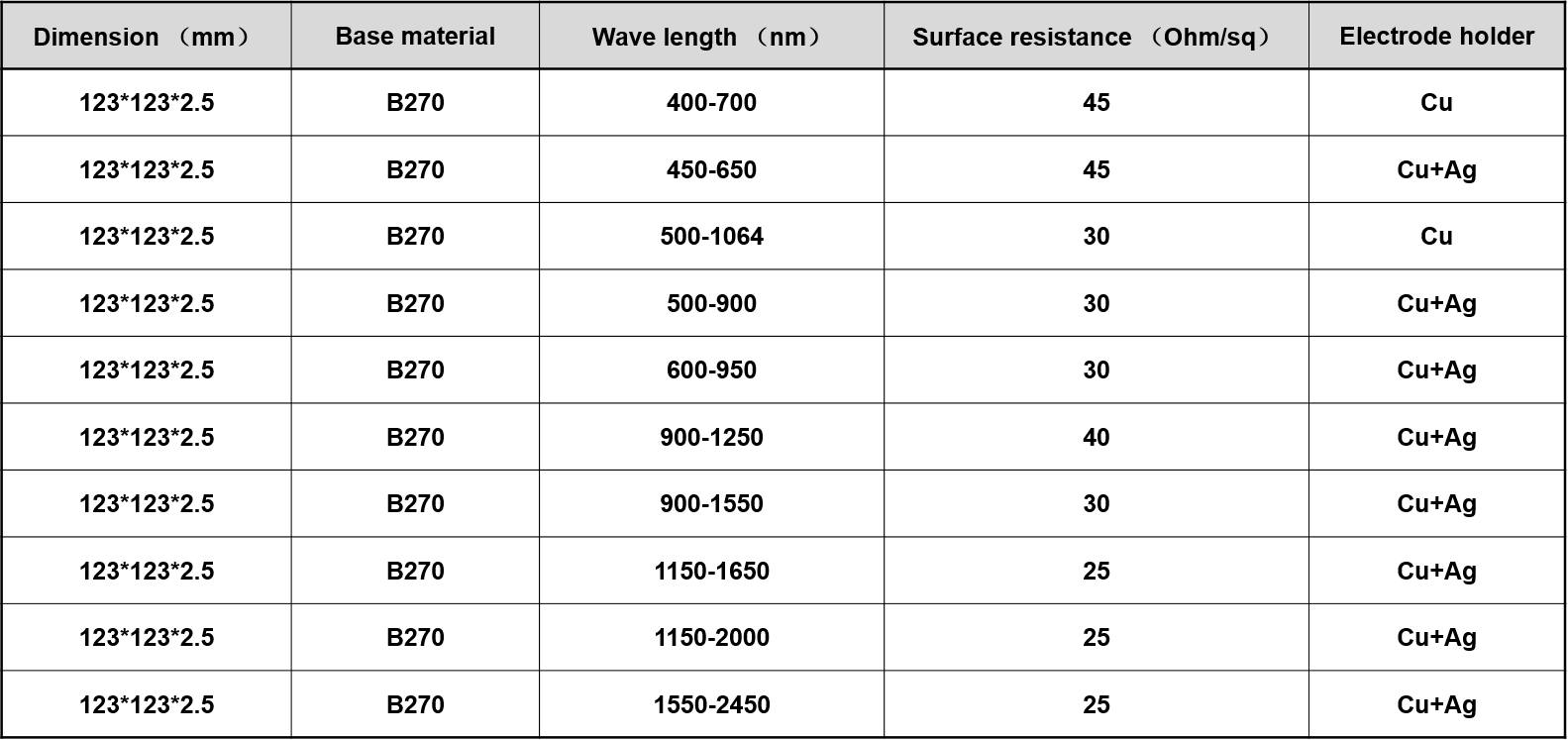

ITO (Indium Tin Oxide) coatings can be applied on glass as well as on plastic.

- On plastic ITO is applied under vacuum at lower temperature. Surface conductivities up to < 10 Ohm-square can be reached.

- On glass a higher temperature can be used and therefore surface resistance can be reduced to < 2,5 Ohm-square.

ITO coated windows are mainly applied for:

- EMI/RFI shielding

- ESD (protection against electro static discharge)

- heated optical filters for displays

- active components for touch-screens

Antireflection possibilities with mineral glass

- Multi-layer coating according to MIL SPEC 675 B (less than 0,6% rest of reflection)

- Single-layer coating according to DIN 58197 (less than 1,5% rest of reflection)

- Chemical etching:

5% anti reflecion (called GW 80)

9% anti reflection (called GW 100)

13% anti reflection (called GW 120)

Antireflection possibilities with plastic substrates

- Multi-layer coating according to MIL SPEC 675 B (less than 0,6% rest of reflection)

- Single-layer coating according to DIN 58197 (less than 1,5% rest of reflection)Chemical etching (very diffuse)

- Chemical etching (very diffuse)

- Anti-scratch, anti-reflection coating by spraying